Approved flexible water connectors are approved for water supply to heater within the enclosure only.A cold water shut off valve shall be installed for the service or replacement of the water heater.

Single wall vent connector must be secured to down draft diverter and type-B vent with sheet metal screws.Double wall vent is required outside of the enclosure. Double wall type-B vent requires minimum one-inch clearance to combustible materials.Gravity vents shall extend in a generally vertical direction with offsets not exceeding 45 degrees. Termination of type-B vent shall be minimum 4 feet from the property line.Verify approved location with staff at the Planning counter. Shed clearance to side property line is two feet, six inches and three feet to rear property line.Typical Installation of Water Heater in Metal Shed Metallic gas piping must withstand 10 psi air pressure for at least 15 minutes without leaking.Water piping must withstand the street main pressure or 50 psi pounds per square inch (psi) of air pressure without leaking.No section shall be tested with less than a 10-foot head of water. Drainage, and vent systems must be tested by filling with water and must be watertight.Building sewers shall be tested by plugging the end of the building sewer at its point of connection with the public sewer and completely filling the building sewer with water from the lowest to the highest point.All tests must be witnessed by the inspector. All work must be inspected and approved before being covered, concealed, or put into use.The termination of type-B vents shall be a minimum of four feet from the property line. Verify approved location of the water heater with the Zoning counter staff. Shed clearance to side property line is two feet, six inches and three feet to rear property line. Water heaters which depend on the combustion of fuel for heat shall not be installed in any room used or designed to be used for sleeping purposes, bathroom, clothes closets, or in any closet or other confined space opening into any bath or bedroom. Need to relocate or increase the capacity of your gas meter? Visit the Long Beach Energy Resources Department website for information.

The pressure shall be held without induction of additional air for a period of at least 15 minutes. The air test shall be made by attaching an air compressor testing apparatus to any suitable opening, and, after closing all other inlets and outlets to the system, forcing air into the system until there is a uniform gauge pressure of 10 pounds per square inch. Once all gas pipes has been installed, perform an air pressure test on the new gas system.

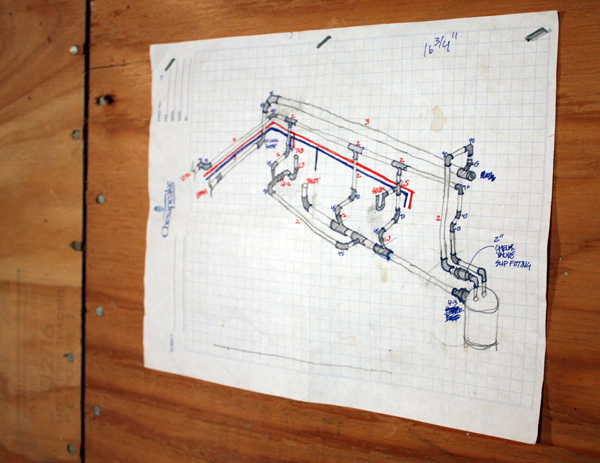

#PLUMBING ROUGH IN SLAB DIAGRAMS PLUS#

The distance from the meter to the most remote outlet plus the gas demand of the appliance served determines the size of each section of gas piping system.Unions for gas pipe are only permitted at an exposed fixture appliance or equipment connection and in exposed exterior locations immediately on the discharge side of a building shut off valve.Gas piping shall not be installed in the ground unless it is protected against corrosion by a machine applied coating or wrapping.The gas pipe can be attached to the raised wood floor joists minimum 6” above grade. Gas piping may not be installed underneath the raised floor of a building when the gas line is in the ground or under/within a concrete floor slab of a building.

0 kommentar(er)

0 kommentar(er)